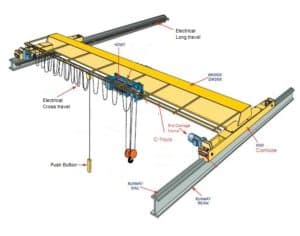

Single Girder Overhead Crane

Single Girder Overhead Crane is the most common crane type installed in factory and warehouse. It Utilizes a single bridge beam (girder) attached to the two runways and end carriage (saddle). This bridge beam or single girder supports a lifting mechanism or hoist that runs on the bottom flange of the bridge beam (girder). There are two types of single girder overhead crane, top running (see picture) and under running or under hung crane.

Single Girder Overhead Crane is most frequently used for low lifting loads between 1 ton to 10 tonnes and or spans of 6 meters up to 25 meters. It has slightly lower lifting height than double girder overhead crane but with more cost efficient to build.

Advantages of single girder overhead crane:

1. Less dead weight than double girder overhead crane. less dead weight means less cost.

2. Great working area coverage

Single Girder Overhead Crane is a crane type that utilize a single beam (girder). The beam (girder) is made from H beam, Wide flange beam or S beam for spans below 12 meters and or lifting loads up to 5 tonnes. As for above 12 meters span and or above 5 tonnes load, the beam (girder) usually made of built up box steel plate. Integra Crane design and analyze the strength of built up box beam using latest computer aided design to give you maximum rigidity with the least dead weight.

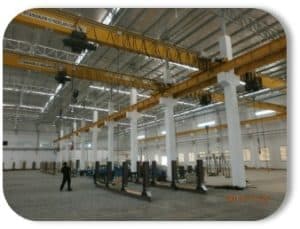

The installation or erection of the crane has to be done by professional to ensure it is safe and the crane is working properly. Runway beam level and spans consistency between runway beams has to be considered before installation in order to prolong the life time of the crane.

The installation or erection of the crane has to be done by professional to ensure it is safe and the crane is working properly. Runway beam level and spans consistency between runway beams has to be considered before installation in order to prolong the life time of the crane.

Through our experience and knowledge, Integra Crane designs and manufactures single girder overhead crane with the least dead weight and maximum safety, these are to make sure that our customers get the most efficient, safe, reliable and durable crane systems.

Contact us for further discussion or

Take a look on our previous crane projects